Stamped Eyelets

Available in Stainless steel or zinc plated carbon steel. Other sizes available.

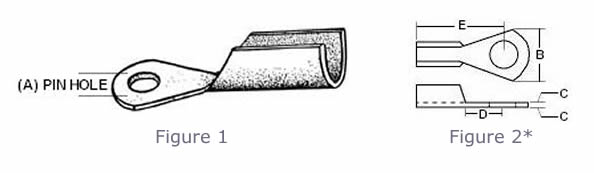

*Before Swage

Eyelet part #2303-03 swaged with a Cont. Cable 50 Ton Hydraulic swager onto 3/32" 7 x 7 cable.

| To Fit Cable Dia. |

Part Number |

A Pin Hole |

Material Type |

Approx. Weight Per 100 Pcs. (Lbs) |

B | C | D | E |

| 3/64 | 2083-01.5 | .160" | Z.P. | .38 | .320 | .060 | .315 | .715 |

| 3/64 | 2081-01.5 | .160 | S.S. | .38 | .320 | .060 | .315 | .715 |

| 3/64 | 2023-01.5 | .190 | Z.P | .35 | .320 | .060 | .315 | .715 |

| 3/64 | 2021-01.5 | .190 | S.S. | .35 | .320 | .060 | .315 | .715 |

| 1/16 | 2093-02* | .129 | Z.P. | .25 | .380 | .035 | .340 | .650 |

| 1/16 | 2091-02* | .129 | S.S. | .25 | .380 | .035 | .340 | .650 |

| 1/16 | 2103-02* | .194 | Z.P. | .24 | .380 | .035 | .340 | .650 |

| 1/16 | 2101-02* | .194 | S.S. | .24 | .380 | .035 | .340 | .650 |

| 1/16 | 2313-02 | .129 | Z.P. | .74 | .460 | .060 | .400 | .978 |

| 1/16 | 2003-02 | .190 | Z.P. | .69 | .430 | .060 | .320 | .940 |

| 1/16 | 2001-02 | .190 | S.S. | .69 | .430 | .060 | .320 | .940 |

| 1/16 | 2013-02 | .260 | Z.P. | .63 | .430 | .060 | .320 | .940 |

| 1/16 | 2011-02 | .260 | S.S. | .63 | .430 | .060 | .320 | .940 |

| 1/16 | 2173-02 | .204 | Z.P. | .65 | .460 | .060 | .400 | .978 |

| 1/16 | 2171-02 | .204 | S.S. | .65 | .460 | .060 | .400 | .978 |

| 3/32 | 2303-03 | .205 | Z.P. | 1.92 | .500 | .093 | .470 | 1.42 |

| 3/32 | 2301-03 | .205 | S.S | 1.92 | .500 | .093 | .470 | 1.42 |

| 3/32 | 2343-03 | .250 | Z.P. | 1.88 | .500 | .093 | .470 | 1.42 |

| 3/32 | 2341-03 | .250 | S.S. | 1.88 | .500 | .093 | .470 | 1.42 |

| 3/32 | 2323-03 | .375 | Z.P. | 2.04 | .750 | .093 | .450 | 1.31 |

| 3/32 | 2321-03 | .375 | S.S. | 2.04 | .750 | .093 | .450 | 1.31 |

| 3/32 | 2333-03 | .500 | Z.P. | 1.81 | .750 | .093 | .450 | 1.31 |

| 3/32 | 2331-03 | .500 | S.S. | 1.81 | .750 | .093 | .450 | 1.31 |

| 1/8 | 2403-04** | .250 | Z.P. | 4.66 | .580 | .125 | .480 | 1.95 |

| 1/8 | 2401-04** | .250 | S.S. | 4.66 | .580 | .125 | .480 | 1.95 |

| 1/8 | 2413-04** | .316 | Z.P. | 4.64 | .580 | .125 | .480 | 1.95 |

| 1/8 | 2411-04** | .316 | S.S. | 4.64 | .580 | .125 | .480 | 1.95 |

| 1/8 | 2423-04 | .375 | Z.P. | 4.92 | .850 | .125 | .540 | 1.84 |

| 1/8 | 2421-04 | .375 | S.S. | 4.92 | .850 | .125 | .540 | 1.84 |

| 1/8 | 2433-04 | .500 | Z.P. | 4.56 | .850 | .125 | .540 | 1.84 |

| 1/8 | 2431-04 | .500 | S.S. | 4.56 | .850 | .125 | .540 | 1.84 |

* 2093-02, 2091-02, 2103-02, and 2101-02 holds 250 lbs. max. without distortion to eyelet.

** 2403-04, 2401-04, 2413-04, and 2411-04 holds 1600 lbs. max.

Cautions & Warnings

Stamped eyelets must be assembled with a mechanical or hydraulic swager using properly designed dies.

A pull test should be performed to determine the holding strength of the applied eye, and suitability for your application.