Custom Wire Rope Cable Assemblies

Engineered to Perform - Since 1969

At Continental Cable, we specialize in the manufacturing of high-quality custom wire rope cable assemblies. As a MIL-DTL-83420 qualified manufacturer, we deliver precision-engineered assembly solutions that meet the most demanding performance and compliance standards.

Wire Rope Cable Assemblies: Custom Engineered Strength for Every Application

Wire rope cable assemblies are essential components in industries where strength, safety, and precision are critical. Whether supporting architectural structures, securing marine equipment, or enabling movement in aerospace applications, these assemblies deliver durable performance and long service life.

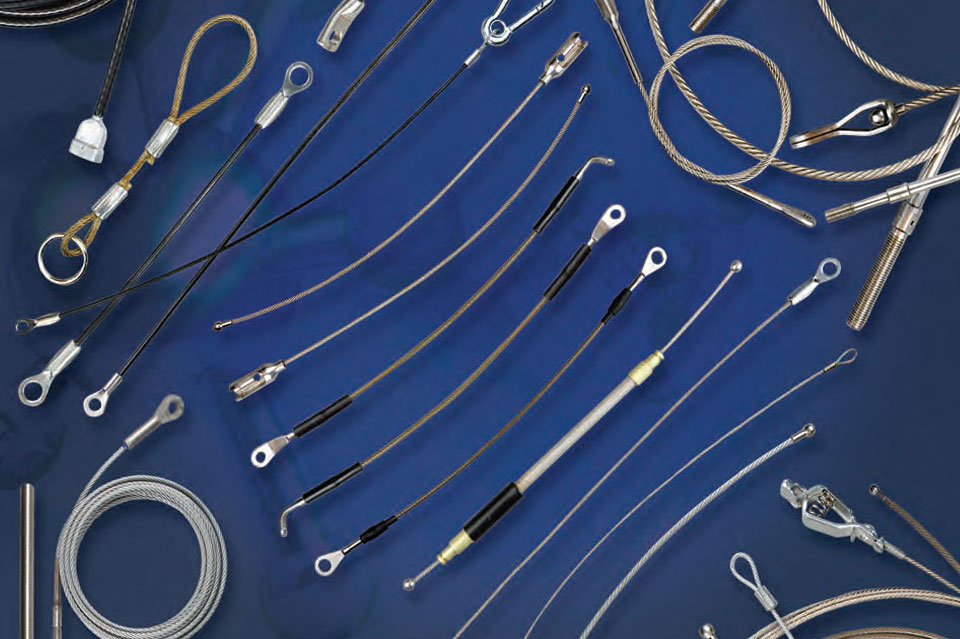

Our wire rope cable assemblies combine engineering precision with rugged performance, making them indispensable in a variety of industries and OEM applications. Whether you need stainless steel cable railing, swaged fittings, or fully custom wire rope assemblies, partnering with an experienced manufacturer ensures long-lasting, safe, and efficient solutions. Our custom cable assemblies are tailored to ensure exact fit, strength, and functionality across a wide range of industries, including defense, aerospace, telecommunications, medical, automotive, and industrial machinery.

Leveraging modern manufacturing technology alongside comprehensive engineering insight, we produce fully customized cable assemblies to match your specific application requirements. Whether you're managing a high-volume production run or short run, our experienced team works closely with you to ensure the best-performing, most reliable cable assembly, on time and to spec.

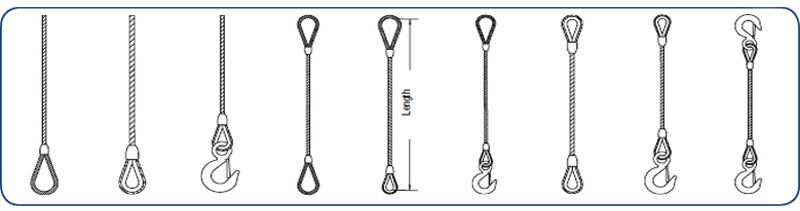

Wire Rope Cable Assemblies Offered

Cable Assembly Types

- Cable Lanyards

- Eyelets

- Sleeves

- Stops

- Threaded Studs

- Ball and Shanks

- Zinc Die cast

Customizable Cable Assembly Features

- Part marking

- Heat shrink tubing

- Colored PVC coated cables

- Nylon coated cables

Our engineers will work with you to provide the optimal, highest quality assembly, for your project and for orders of every size.

Applications - Where Wire Rope Cable Assemblies Are Used

Custom wire rope assemblies are integral to countless applications that demand strength, safety, and control:

- Lifting

- Pulling

- Securing

- Connecting

- Suspension

- Reeling In

Whether you need standard or a special cable assembly, cable lanyards, eyelets, stops, sleeves, and more, Continental can deliver you the finished product.We will make custom fittings to meet your requirements and assist you from inception to completion. Let our Sales Team help you out today.